Cross flow filtration – a filtration process in which feed water flows tangentially across a membrane surface – is widely utilized in water and wastewater filtration. The turbulence created across the membrane surface provides optimal flux performance and prolongs filter functionally. Cross flow filtration works by introducing feed water under pressure across the membrane surface, instead of directly onto the filter. During filtration, any material smaller than the cross flow membrane pore passes through the membrane, while larger suspended particulates remain in the retentate stream.

Cross Flow Filtration and Dead-End Filtration

There are two major competing types of filtration technologies used in industrial processes: dead-end filtration vs cross flow filtration. In dead-end filtration, the solids collect on the surface of the filter media as a stable filter cake that grows in thickness and increases flow resistance. The filter media is usually a consumable component disposed of with the filtered solids.

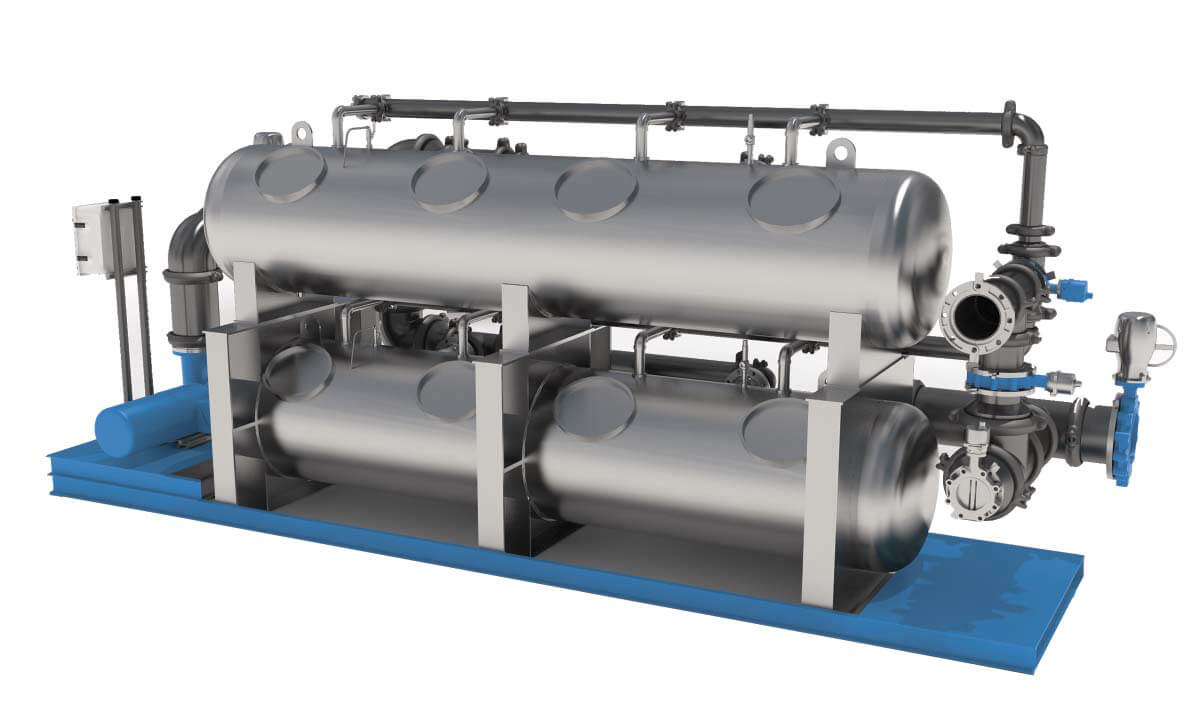

In the cross flow filtration process, the concentrate feed water flows across the surface of a membrane filter media with minimal solids buildup and at constant low flow resistance. The membrane is not a consumable component. The differences in these two filtration processes are displayed in the graphic below.