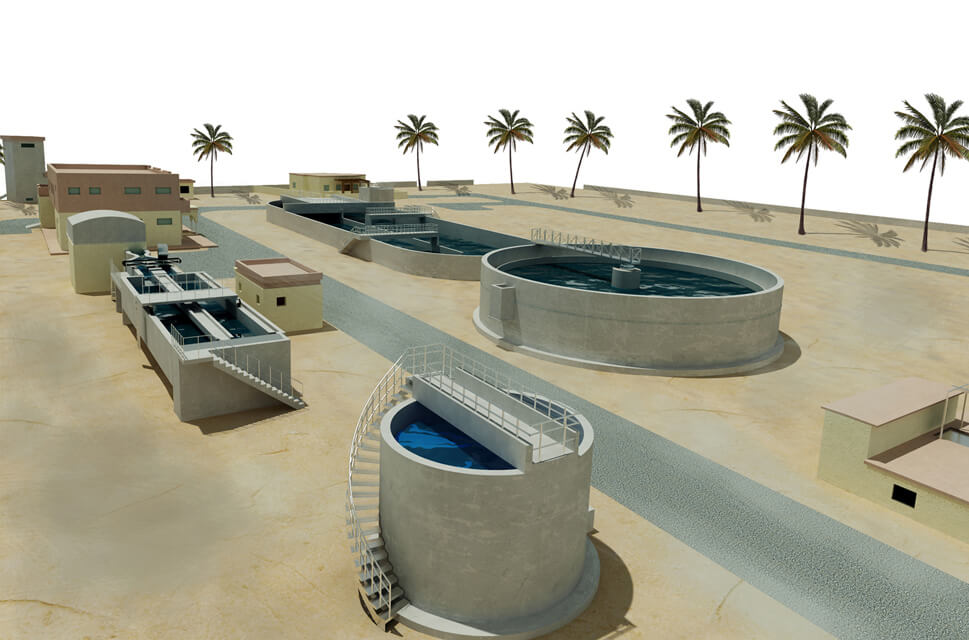

As effluent water quality regulations have become more stringent, the need for high-quality municipal wastewater treatment solutions has continued to grow.

We can supply different processes for wastewater treatment including:

Sludge handling (Wastewater)

Sewage sludge is a byproduct of treated wastewater. It is composed of both organic and inorganic materials, a large concentration of plant nutrients, organic chemicals, as well as pathogens. Therefore, it is extremely important to properly treat such sludge in order to minimize its environmental repercussions. Here is a brief overview of the sludge treatment process to help gain a better understanding of the treatment techniques and process requirements:

Step 1 – Sludge Thickening

The first step in the sewage sludge treatment plan is called thickening. In this step, the sewage sludge is thickened in a gravity thickener to reduce its overall volume, thus enabling the easy handling of the sludge. Dissolved air flotation is another alternative that can be used to effectively to thicken the sludge by using air bubbles to allow the solid mass to float to the top.

Step 2 – Sludge Digestion

After amassing all the solids from the sewage sludge begins the sludge digestion process. This is a biological process in which the organic solids present in the sludge are decomposed into stable substances. This process also helps reduce the total mass of solids, while destroying any present pathogens to enable easy dewatering.

Step 3 – Dewatering

After retrieving useful gases and other byproducts, the remaining sludge is then dewatered before final disposal. In most cases, dewatered sludge usually contains a significant amount of water, as much as 70 percent, in spite of its solidified state. Therefore, it is important to dry and dewater the sludge beforehand. While using sludge-drying beds is the most common way to carry out this process, it is extremely time-consuming and may take weeks before the process is complete. In order to quicken these processes, waste management plans are also employing solid-liquid separation devices to carry out this process. One of the alternatives include the rotary drum vacuum filter and the belt filter press.

Step 4 – Disposal

Once the sludge has been effectively dewatered, it can be buried underground in a sanitary landfill or can be used as a fertilizer, depending on its chemical composition. In cases where the sludge is too toxic to be reused or buried, you can simply incinerate the sludge and convert it into ash.