Double-Pass RO

Double-Pass ROTo understand how reverse osmosis works, it helps to understand the process of osmosis which is ubiquitous in nature. When two solutions having different dissolved mineral concentrations are separated by a semi-permeable membrane, water flows from the less concentrated solution to the more concentrated solution. Examples of semi-permeable membranes are cell walls of a living organism, the membrane on the inside of a chicken egg.

Reverse osmosis systems utilize man-induced pressure on the “dirty side” (high mineral content side) to overcome the natural osmotic pressure trying to flow the other way, plus some added pressure to speed the process in order to force water across the semi-permeable membrane to the “clean side”. In the RO process, 98% or more of the dissolved minerals are left behind on the “dirty side”.

This produces a very clean product water since even very small particles (down to 0.0001 micron), including most total organic carbon or TOC is also removed.

Reverse Osmosis is an ideal water treatment solution in most types of water. Generally speaking, all major water sources from a treatment standpoint can be broken down into three major categories: tap water, also known as municipal sources, groundwater, which includes brackish water, and saltwater. The biggest distinction between these three types is the Total Dissolved Solids (TDS) content of each type.

Sea Water RO skid with Energy Recovery

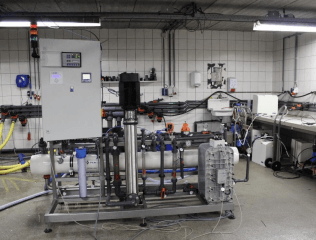

RO-EDI during FAT

If the feed water is properly treated upstream of the reverse osmosis system (effective filtration), maintenance is generally minimal since they only have one significant moving part, a pump. The most prevalent RO membranes in use today are susceptible to destruction by chlorine so pretreatment generally includes either feeding a reducing agent like sodium bisulfite or use of activated carbon filters to achieve dechlorination (i.e., elimination of free chorine). Ion exchange softening may be required to reduce calcium and magnesium carbonates to prevent scaling, although the rapid development of Antiscalant chemicals generally makes them the method of choice (eliminates salt consumption). Multi-media filtration may be required if the water contains significant silt. Feed water should be evaluated using a silt density test (SDI) prior to specifying pretreatment since premature membrane failure and / or frequent membrane cleanings could result from inadequate pretreatment design. The SDI is a unit-less number calculated from several timed collections of water flowing through a 0.45-micron absolute filter while maintaining a pressure of 30 psi.